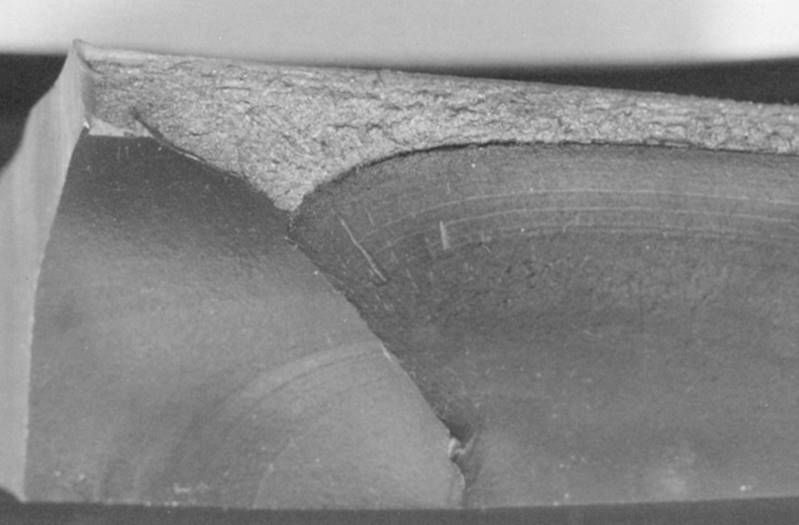

Large Region of Spalling Damage on Ball Bearing Raceway

Whenever practical, analytical predictions should be performed in concert with failure analyses to completely understand and successfully diagnose problems associated with the operation of rotating equipment. Over the years, RBTS has provided its customers with failure analysis support to address existing problems. In addition to using our own eyes, we routinely utilize both light and electron microscopy to facilitate our evaluations. When needed, we can arrange for specialized testing such as: material mechanical strength and fatigue, dimensional verification, and lubricant analysis.

High Cycle Fatigue Failure in Turbine Rotor

Common support areas where RBTS has provided failure analysis services include:

To learn more about our failure analysis support, please contact RBTS. Sample applications and a description of the services provided are available in our photo gallery.